When it comes to this situation, weld neck flanges any flange will do the trick. However, when designing the component, it is essential to decide whether the integral flange or the loose flange should be used. The degree of integrity possessed by the flange ring and the straight cylinder section should be taken into consideration when making this decision. The flat welding flange, in contrast to the neck butt welding flange, features a construction that is more straightforward and a design that is more straightforward. On the other hand, the rigidity and sealing performance of the flat welding flange are nowhere near as good as those of the neck butt welding flange. This is especially true when comparing the flat welding flange to the neck butt welding flange.

Because the diameter of the seal has been made smaller, the size of the compact flange has also been made smaller. This has the effect of reducing the cross-section of the sealing face, which is a positive development. The flange gasket has been replaced with a sealing ring so that the sealing surface can be machined. This step was taken in order to facilitate step two. This was done so that the surface of the seal could be machined. A welding flange that is flat not only ensures that the joint will not leak and will stainless steel flange have excellent sealing performance, but it also reduces the amount of space that is required for the joint. This is in addition to cutting down on the amount of weight that is required for the joint.

Because of this, the diameter of the bolts will ASME B16.47 Flanges need to be increased before they can be used. Because nuts with larger diameters need to be mated with bolts that are larger in diameter, nuts with larger diameters need to be used with bolts that have a larger diameter. Because of this, it is impossible to screw the nuts in any further because there is no more room.

Polishing techniques such as hand-polishing, mechanical polishing, chemical polishing, and electrochemical polishing can all be used on dual-phase steel flanges. As a result of the polishing and cleaning process, some chromium and phosphorus will be discharged into the waste water. Because of the microscopically inconsistent surface of the dual-phase steel flange, the microconvex part on the surface dissolves preferentially, and the rate of dissolution will be higher than it wouldBecause of the microscopically inconsistent surface of the dual-phase steel flange, the microconvex part on the surface dissolves preferentially, and the rate ofThe roughness that was previously present on the surface of the duplex steel flange has been smoothed out, and as a result, the surface is now glossy and smooth. Both of these prThe entire device will require enormous size and weight, which becomes a particular problem in the offshore environment. Because of the microscopically inconsistentBoth of these processes will take place at the same time as a result of the microscopically inconsistent surface of the.

3. This is accomplished by filling in the surface scratches and pores. It possesses sufficient plasticity and toughness for this forming, in addition to excellent resistance to stress corrosion cracking, particularly in environments rich in chloride ions. This is especially true in environments where there is a high concentration of chloride ions. Flanges made of duplex steel have yield strengths that are more than twice as high as those made of austenitic stainless steel. Additionally, it can be formed without fracturing as a result of stress. This is especially helpful in situations where there is a high concentration of chloride ions in the environment.

1. The gasket undergoes chemical changes as a result of the corrosion effect, the corrosive medium penetrates into the gasket, the gasket begins to soften, loses compressive force, and this results in flange leakage. 2. The corrosive medium breaks through the gasket, which will result in a lessening of the tension that is already present between the two flanges. In addition to this, it will result in the sealing surface of the sealing surface becoming deviated, which will significantly increase the likelihood that there will be a leak.

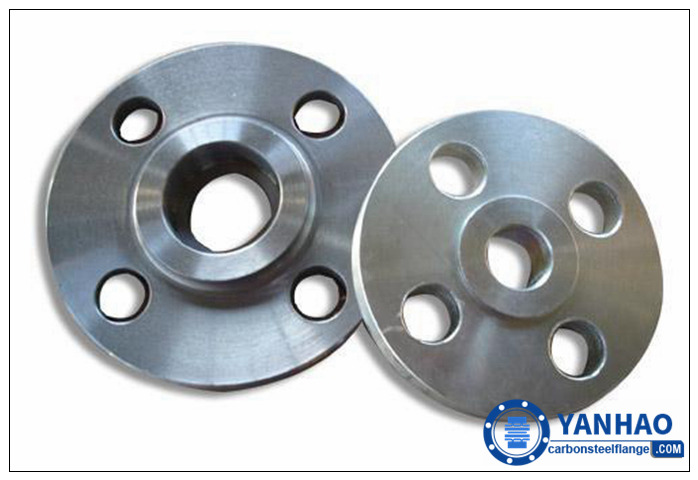

Slip-On Flanges 3. Flange leakage will take place whenever the load pressure of the gasket is higher than the pressure of the internal medium. When the flange clearance is too large, it will cause external loads (such as axial loads or bending loads), which will cause the gasket to be impacted or vibrated, lose the compression force, and gradually lose the kinetic energy of the seal, which will cause the flange to leak. The lack of proper installation or maintenance is typically the cause of this issue, and the solution is not overly difficult to find. When the flange clearance is too large, it will cause external loads (such as axial loadsBecause of the pressure that is present, the preferred method for installing flanges is the butt joint of two adjacent flanges. However, the temperature of the pipeline will change during the manufacturing process of the system after it has been introduced to the medium. This problem can be avoided by ensuring that the flange clearance is as minimal as possible. 4. Leaking flanges Because of the pressure that is present, the preferred method for installing flanges is the butt joint of two adjacent flanges. This will result in the pipeline becoming more distorted or expanded, and as a consequence, the flange will be subjected to bending load or shear force, which will easily result in the gasket failing. This will cause the pipeline to expand or deform.

6. A wrong hole occurs when the pipe and the flange are concentrically aligned with one another, but the space between the two bolts is larger than the bolt hole. The thermal expansion and contraction of the fluid medium, in addition to the expansion or contraction of the bolt, will cause the gasket to have a gap, which will allow the medium to leak through the pressure. The expansion and contraction of the fluid medium will also cause the bolt to expand or contract. This gap may also be the result of the bolt expanding or contracting in size. The term "wrong hole" refers to the situation in which this gap occurs.